| ID |

Date |

Author |

Type |

Category |

Subject |

|

22

|

Wed Feb 15 15:39:16 2006 |

Alec | Other | Setups | Legacy TRXS lineup document |

Beginnings of a startup procedures for peridot and mica.

1) login as user1 to topaz

2) run winspec or winspecperidot to open windows on needed machines

(Use these shell scripts since they work without having to

keep extra windows around on topaz.)

3) start specs, the first time should use "spec -f" or "fourc -f"

to perfrom fresh starts.

(use fourc on peridot and mica and spec on emerald and talc)

3.1) define data file and plot stuff (i.e. run startup)

3.2) Check current spectrometer conditions. It is a good idea to print

all motor positions at the beginning and end of every run and

paste them in the log books.

3.2.1) In particular check s1 slit openings and mirror height (t2_z )

(t2_z ~ 0.0 is Pt stripe -8.1 is Si stripe)

For reference, here are emerald's settings (Sept 12, 2001)

I believe s1 slits are fully open and note that front mirror

is on Pt stripe (t2_z~0.0 conditions for third harmonic).

t1_x t1_z t2_x t2_rot t2_z undgap

1.1270 0.0520 -0.1800 0.6825 0.7500 19.0000

1.1270 0.0520 -0.1800 0.6825 0.7500 -19.0000

s1hgap s1vgap s1hcen s1vcen

0.2000 0.4997 0.0305 -0.5280

0.2000 0.4995 0.0305 -0.5280

3.2.2) To change between first and third harmonic:

a.) "mv t2_z 0.0" (for third) or "mv t2_z -8.1" (for first)

b.) lup t2_rot -.02 .02 40 1 (check mirror angle)

c.) mv t2_rot CEN (center it)

(It appear this changes the beam height in the E hutch by ~2mm.)

4) Check general stuff:

check appropriate motors are on,

check for He flow in flight paths

two full turns to flush (~1/2hr)

set to 0.05 for normal operations

make sure return and supply read same flow rates

(i.e. no big leaks)

(Replacement He tanks are in gas storage at loading dock,

cylinder cart in Chem lab.)

check counter channels are connected right

check offset voltages

check attenuator configuration (CCD shutter hooked up?)

check which detector is in beam

5) with shutter closed move diamond mono into beam

typical positions are (out of beam): (Sept 12, 2001)

diamth diamx diamz diamchi

22.5435 -0.7900 3.2003 -2.8880

22.5435 -0.4550 3.2003 -0.6580

typical positions are (in beam):

diamth diamx diamz diamchi

22.5435 -0.7900 -15.6098 -2.8880

22.5435 -0.4550 -15.6098 -0.6580

6) open shutter and check alignment:

Typical count rates are (Iring~100mA):(keithley is 0.000e-9)

Full beam ionc1: 6e5

.9x.6mm^2 ionc1: 4e5

.9x.6mm^2 ionc2: 3e5

.9x.6mm^2 pind: 3e5 (Tramp gain 10e5)

7) Check diamth.

Best way is to use large pindiode taped to Be window

on monochromator. This gives almost full harmonic spectrum.

(See TRXS book 4 page 60.) Get 3e5 cps at tramp gain 1e4.

A quick check is to open ss1hgap fully and should see peak

as rounding of intensity (Book 4 page 131, note Int spikes

when beam hits ion chamber blades.)

Can rock diamth, diamchi, diamz and diamx (see book 4, page 52).

(usually on diamth is needed).

8) line up slits.

close ss1hgap to .9mm and scan ss1hcen to center on beam,

use ionc1 (or icon2) as detector. repeat for ss1 vertical

and ss2 vertical and horizontal.

(may need to check gaps are correct. do "ascan ss1hgap 0 .5 25 1"

and check zero intensity point.) The current ss1 are regular

Huber blades. The ss2 have Tl blases offset so a -.2 mm gap can

be made without the blades touching. (Note XIA slits can not have

negative dial units but one can make user units be -ve.)

9) check spectrometer centering.

For the TRXS spectrometer there is a way to mount a Huber 1000

head with a centering pin. You can then center the beam on this

pin and check for tth arm centering using the reference iris which

mounts on the tth arm.

On the HS spectrometer ... (to be done).

10) ready to go, here are some helpful hints:

CZT amptek is set to gain 8.0 and 7.62keV peak is around channel

100. Qdo macros/pscan3.mac and use set_sca 80 120 to make sca

detector channel work.

Have set up macros nwa and nlup which I like better then wa and lup. |

| Attachment 1: trxs-table.ps

|

|

21

|

Wed Feb 15 15:37:54 2006 |

Alec | 8-ID-E | Setups | Legacy TRXS description document |

TRXS setup:

The vertical spectrometer consists on a 2 circle diffractometer Huber 420.

With a chi & Phi rocking stage 5203.2

TRXS table:

1- Z motion:

min height: 19.25 inches (table on wheels)

max height: 25.06 inches

(height from top surface)

stz: stzdi,stzdo,stzu

(upper limit switches set within 2-3 mm of physical limits)

Travel range from min height:

stzu: 156.4 mm; stzdi: 153.0 mm; stzdo: 146 mm |

|

20

|

Wed Feb 15 15:25:37 2006 |

Alec | Other | Controls | Legacy table potentiometer information |

Legacy table potentiometer information from the 8-ID web site:

How do I use the potentiometers on the t2 table in the A hutch

1.) Connect +10V to the red lead on the potentiometer

2.) Connect ground to the black lead on the potentiometer

3.) Connect a 5 digit Voltage probe between the yellow lead (+) and

the black lead (-) |

|

19

|

Wed Feb 15 13:32:36 2006 |

Alec | 8-ID General | EPS | EPS Trip |

What to do on an EPS trip

The main (manual) EPS control and display panel is located between the E and I stations

in a mini-rack mounted on the blue, outboard, sector partition wall.

If the EPS trips, then the beacon light beside the main display panel will flash red and will emit

an audible beeping sound.

The EPS logic is such that it will attempt to close the minimum number and most localized (to the problem)

vacuum valves and/or shutters.

A description of how to use use the main EPS panel to review, acknowledge and clear alarms will follow. |

|

18

|

Wed Feb 15 13:17:54 2006 |

Alec | 8-ID-E | Procedures | Legacy Zone plate set-up information from old web site |

Legacy Zone plate set-up information from old web site:

Initial description of setting up zone plate spectrometer.

0) check current configuration on ruby, and maybe count rates.

Run "lpstuff nwa" and put in log book.

1) run winzpspec on user1@quartz and start spec on various machines

(lapis, ruby, emerald (talc?)).

1.1) start spec on emerald.

1.2) start spec on lapis (freshstart (-f) ???)

1.3) start spec fresh on ruby. (spec -f)

1.4) run startup (name datafile: spec/data/rubymondd.yy).

Make sure dac2 motor is at 5.000 and check att value.

Check s1, jj, s2, s4 slits are open enough.

2) move table:

2.1) Connect up X95 flight path.

Add or remove appropriate extension and put large Kapton window

on X95 take a burn. Adjust X95 position till beam will exit in

proper place to use X95 to KF16 adapter. Put on this adapter and

add the pind support and using small KF16 junction temporarly add

Kapton window to end.

2.2) Using airpads move te2 table until in correct place

to add KF16 bellows to couple flight paths. Usually, lining up table

by eye is enough.

(make sure table is parallel to the beam, this can be done by taking

marks on the floor at the upstream and downstream corner of table)

2.3) Using burn paper make x-rays go down center of incident KF16

on ZP setup. If done right will get x-rays all the way through

setup. May need to take off Be exit window and use OSA or te2 motions

to center output on exit window. This is a good time to check is

correct place for beam on x-ray eye.

2.4) Hook up bellows and add exit window and pump flight path.

3) put on Huber pin and check centering.

4) line up Huber pin on x-ray beam.

5) line up tth arm with beam. (define as zero)

NOTE: check out the whatswrong file at user1@quartz if problems arise. |

|

17

|

Wed Feb 15 13:15:04 2006 |

Alec | 8-ID General | Controls | X-Ray info (from old web site) |

X-Ray eye info from old web site - not sure of validity:

******* X-RAY EYE *******

Software is in zircon: /home/user1/xrayeye/dt6

Yorick routines are in: xrayeye/routines

Data (images) are stored in: xrayeye/data

To run the program login as user1 go to xrayeye directory and run: gl dt6

commands:

TV,window,cmax=,cmin=,channel=0

Frame grabber can handle four tv inputs (4 channels).

TV,0 // to make tv plot in window 0.

++++++++++++++++++++++++++++++++++++++++++++++++++++++++

WARNING: DON'T USE CTRL-C TO STOP ANIMATION - USE RETURN

++++++++++++++++++++++++++++++++++++++++++++++++++++++++

NTV,0,50 // to make average of 50 frames.

This doesn't do much unless there is random noise.

These two functions are included in "newtv.i"

savimg,name,comment

Save img in a file with name and comment string

This function is included in "imgsav.i"

Other commands:

ccd_bw,lowerlevel,upperlevel

set the voltage levels on the framegrabber. Use help,ccd_bw

for more info.

ccd_read,image,channel,framing

this open camera if needed and reads one image.

TROUBLESHOOTING:

If the computer was rebooted mount /flinthome/

TECHNICAL NOTES:

- FIELD OF VIEW: 2.8 X 2.1 mm

- RESOLUTION: 4.2 microns per pixel

- CAMERA SHUTTER SPEEDS: 0 1/60

1 1/125

2 1/250

3 1/500

4 1/1000

5 1/2000

6 1/4000

7 1/10000

- GAIN SETTING: |

|

16

|

Wed Feb 15 12:09:28 2006 |

Alec | 8-ID General | Setups | 8-ID Energy and Undulator Gap |

| 8-ID's nominal operating energy, except via prior consultation with the 8-ID beamline staff, is 7.45 keV (Undulator Gap=17.60 mm)---our current best estimate is the actual peak energy delivered by the undulator is 100 eV lower than this or 7.35 keV. |

|

15

|

Wed Feb 15 12:02:39 2006 |

Alec | 8-ID General | Procedures | Aligning mirror after a fill |

The procedure to align E and I stations after a beam fill is:

- Check that the undulator gap has returned to its nominal value (see http://8id.xor.aps.anl.gov/elog/8-ID/16)

- Check that the A shutter (FE shutter) has re-opened (should occur automatically via Auto shutter open control)

- Wait 30 minutes for mirror equilibration (eff. Oct. 2005 this is probably no longer necessary or certainly not for 30 minutes but still needs to be investigated carefully)

- From 8-ID-I station spec, follow the procedure in the align_mirror macro:

| Quote: |

def align_mirror '

print "Moving relevant motors to align the mirror t2fine"

umv si1hgap 250.0;umv si1vgap 250.0;

umv si1hcen 1250;

print "moving diamond crystal(E station) out of the beam"

do_sleep(2);

umvr diamx -1;

print "Moving PIN diode (before shutter and att) into the beam"

umv pind1z 11.0;

#shutteroff;att 0;

counters -1 1;plotselect pind1;ct 1;

printf("Counts on PIND1 before alignment = %f",S[pind1])

do_sleep(5);

#lup ta2fine -30 30 30 1;

#umv ta2fine CEN;ct;

lup ta2_rot -.005 .005 25 1;

umv ta2_rot CEN;ct;

#If max. counts is not attained, tw ta2_rot .00025 till you get the counts

#beep;beep;beep;beep;

#print "(umv si1hcen 1500) and (umvr diamx 1) and (umv pind1z 25) and (plotselect pind1)"

'

|

To restore pin diodes, slits, ..., back to their nominal starting position after mirror alignment, follow the procedure listed in the 'restore_mirror' spec macro:

| Quote: |

def restore_mirror '

umv si1hcen 1500;

umvr diamx 1;

lup diamx -.5 .5 20 1;

att 15;shutteron;

print "Moving PIN diode out of the beam"

umv pind1z 25.0;

counters -1 3;

plotselect pind3;

'

|

|

|

14

|

Wed Feb 15 11:56:17 2006 |

Alec | 8-ID General | Controls | How to start EPICS (medm really) |

How to start EPICS or more properly start display the medm display manager:

Enter 'start_epics' (without the single quotes) from one of the 8-ID control computers

(quartz, glass, topaz, pepper or bixbite) when logged in with one of the beamline

user accounts (8ideuser, 8idguser or 8idiuser) |

|

13

|

Tue Feb 14 10:58:59 2006 |

Alec | 8-ID-D | Setups | 8-ID-D monochromator positions |

Undulator Gap = 17.7 mm

Energy (1st Harmonic) = 7.5 keV

--------------------------------

Si(220) as of Aug. 17 , 2005

diamx= -14.2

diamz= -16.0

diamth= 25.854

diamchi= -0.975

diamth(encoder)= 375781

diamth(motorpos)= 469110

--------------------------------

Si(111) as of Feb. 3 , 2005

diamx= -4.75

diamz= 14.00

diamth= 16.38

diamchi= -0.0700

diamth(encoder)= 374464

diamth(motorpos)= 279638

-------------------------------- |

|

12

|

Tue Feb 14 10:05:02 2006 |

Larry | 8-ID General | Other | Discussion of choosing best photon energy for COSAXS |

|

| Attachment 1: ChoosingEnergy.pdf

|

|

11

|

Tue Feb 14 09:42:32 2006 |

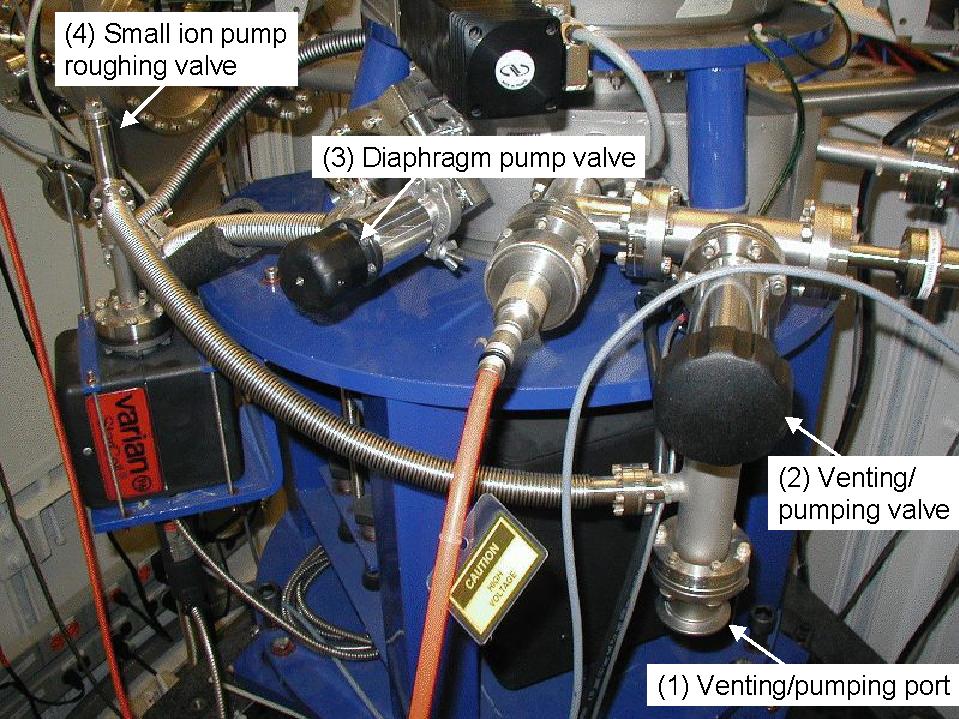

Alec | 8-ID-D | Beamline Hardware | 8-ID-D Monochromator Venting and Pumpdown Procedure |

Diamond Monochromator

pump down & venting procedure

This document is a step-by-step description of the procedure to vent and pump down the Diamond Monochromator vacuum chamber:

Numbers in parenthesis refer to parts labeled in the picture.

See http://8id.xor.aps.anl.gov/elog/8-ID/7 for directions on how to use the monochromator ion pump controller.

Venting

- Close gate valves immediately upstream and downstream of the monochromator

(if you don't know how to do this, it is most likely because you should

NOT attempt to do it!)

- Connect a venting supply of Nitrogen.

Best would be to get the Vacuum/Mechanical engineering group to perform this procedure as they have considerable experience in doing this properly. They will typically vent chambers with boil off from liquid N2.

As a distant second alternative, hook up a nitrogen cylinder to the venting port (1) and set the regulator

to 5 psi. Also, please include a relief valve in the venting assembly.

(In Jan. 2006 there was a a serious accident at 3-ID wherein a Be window was exploded because a relief valve was not used during the bleed up)

- Turn off the ion gauge

- Turn off the ion pumps

- Close the small manual valve for the diaphragm pump (3)

- Put the handle back on the large manual valve (2) and open it slowly

to vent the vacuum chamber (make sure to avoid any pressure build-up inside the chamber)

Pumping

- Hook up a dry pump to the venting port (1) and start pumping

Start the diaphragm pump.

- Open the large manual venting valve (2)

- Open the venting valve for the small ion pump (4) using the torque wrench stored in the monochromator toolbox

- Pump down until the pressure reaches into the 10-6 Torr

- Start the large ion pump (#1)

- Leave the turbo pumping on the chamber until the pressure displayed by the ion pump starts to decrease

- Close the large manual venting valve (2)

- At this point, the turbo is still pumping on the small ion pump

- Start the small ion pump (#2)

- When the pressure displayed by the ion pump starts to decrease, close the

venting valve for the small ion pump using the torque wrench adjusted to 30 lbs/in

(The valve is rated to 2.5 lbs/ft and the wrench (which is calibrated in lbs/in) should be set to 30 lbs/in)

- Make sure Protection Mode is engaged for both pumps

- Turn on the ion gauge

- Stop and then disconnect the turbo pump

- Put a blank on the venting/pumping port (1)

- Remove the handle from the large manual venting valve (2) but leave it in this hutch!....

- Typical pressure is: 5 x 10-7 Torr (it used to considerably better (10-9) before the monochromator

was vacuum-integrated with the 8-ID-E shuuter; now there appears to be insufficient

pumping speed for the whole assembly)

|

| Attachment 1: Mono_valve2.jpg

|

|

|

10

|

Tue Feb 14 09:18:03 2006 |

Alec | 8-ID General | Computers and Network | List of devices on the 8-ID network |

A list of devices on the 8-ID network (or assigned to the network), can be obtained by entering

'ypcat hosts | grep 116' at a command prompt on a Linux workstation/desktop |

|

9

|

Tue Feb 14 09:15:23 2006 |

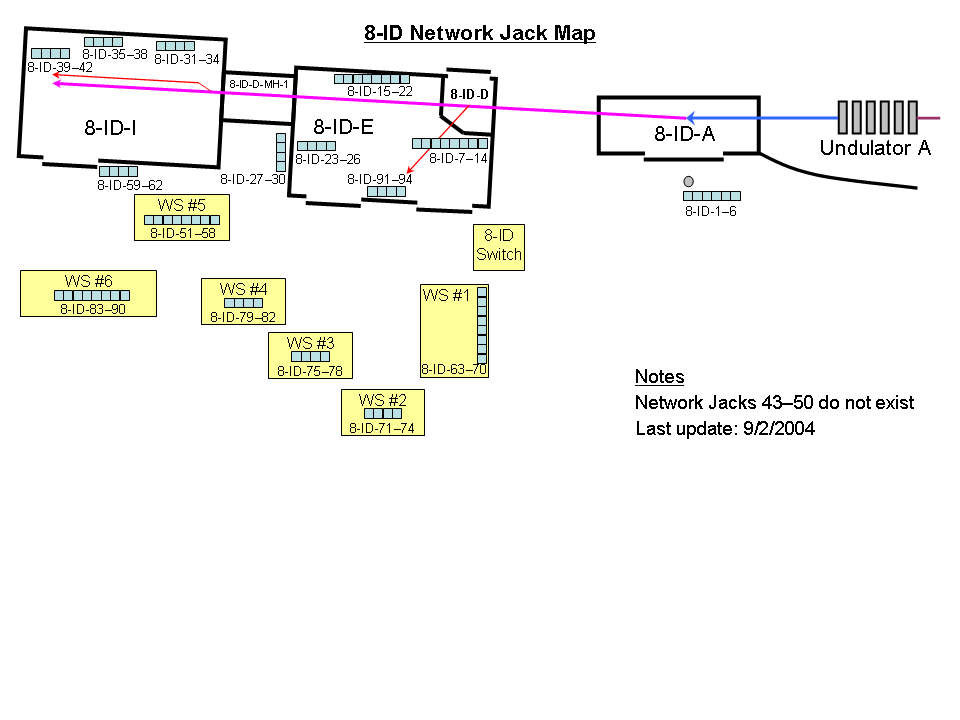

Alec | 8-ID General | Computers and Network | 8-ID Experiment Floor Computer Jack Layout |

| 8-ID Experiment Floor Computer Jack Layout. There should be a one-to-one correspondance to the ports on the experiment floor switch. |

| Attachment 1: JackLayout_20040920.ppt

|

| Attachment 2: JackLayout_20040920.png

|

|

|

8

|

Wed Feb 8 11:05:09 2006 |

Alec | 8-ID General | Detectors | MCA and Multi-element detector set-up info from the X26 at the NSLS |

MCA and Multi-element detector set-up info from the X26 at the NSLS:

http://www.bnl.gov/x26a/comp_med.shtml |

|

7

|

Tue Feb 7 13:37:46 2006 |

Alec | 8-ID-D | Hardware | Monochromator ion pump operation |

Diamond Monochormator ion pump operation instructions

On the controller, ion pump #1 is the larger pump attached to the vacuum chamber and ion pump #2 is the smaller pump hooked-up to the intermediate stage of the rotary seal.

Starting

- Use the Pump Select button to select which pump to operate

- Press Amp/Volt to display voltage

- Press HV ON/OFF for the pump you want to start

(Displayed voltage should be increasing rapidly.)

After about 30 sec., press Start Prot to engage the Protection Mode.

Current should fall in the 10-4 A

Stopping

- Use the Pump Select button to select which pump to operate

- Press Start Prot to disengage the Protection Mode

- Press HV ON/OFF for the pump you want to stop

Protection Mode trip

If the pump stops due to a Protection Mode trips shortly after turning it on, the HV light (amber) will flash. This most likely means that the pump cannot start because pressure is still too high.

In order to re-start the pump, you first have to:

- Press Start Prot to disengage the Protection Mode (green light should be off)

- Press HV ON/OFF so that the HV light is off

|

| Attachment 1: Mono_ionp_ctr.jpg

|

|

|

6

|

Mon Feb 6 17:24:05 2006 |

Xuefa | 8-ID-E | Setups | Si(220) beam position on the Entrance Be window |

I estimated the minimum distance from the diamond crystal to the top side of the exit flansch to 675 mm, assuming the following bragg angles at 7.4keV (100eV removed from actual Undulator settings), Si(111) 31.0 deg and Si(220) 51.8 deg and using the separation of the two burn spots measured by Xuefa. This means, that the distance crystal to the Si(111) exit port is 740 mm and the distance crystal to the Si(220) exit port is 676 mm.

Michael

Xuefa measured the beam on the entrance Be window on Si(220) line to be 553 mm from the inboard edge of the flange.

Xuefa measured the beam on the entrance Be window on Si(111) line to be 287 mm from the inboard edge of the flange.

Xuefa

Feb.06,2006 at 5-23 pm |

|

5

|

Mon Feb 6 16:37:25 2006 |

Alec | 8-ID General | Detectors | MCA Setup |

One should remember to this ...

| Quote: | | The attached documents describe how to set up the Canberra MCA that belongs to 8-ID. These documents assume that the MCA is configured in EPICS and the devices themselves are in a powered-up NIM bin and are connected to the 8-ID network. The Powerpoint has been included so that it may be edited and re-uploaded |

|

|

3

|

Mon Feb 6 16:26:02 2006 |

Alec | 8-ID General | EPS | Legacy EPS wiring |

| Legacy (pre switchover to ASD-SI in 2004) wiring diagram for the EPS. Also, does not include the slave IOC's added to 8-ID-E and 8-ID-I. |

| Attachment 1: plc_wiring.asc

|

FILE /home/larry/Documentation/EPS/Spread/plc_wiring.sc

PLC PINOUTS

All contact are sinking configuration

Wed Jan 19 10:51:31 2000

IO Function TB PLC

INPUT POINTS

X0 Front End Shutters Closed a1,e10 (A) a0

X1 Front End Valve Closed a3,e12 (A) a1

X2 Flow #1 L5-80 a5,f1 (A) a2

X3 Flow #2 Mini Aperture a7,f2 (A) a3

X4 Flow #3 a2,f3 (A) a4

X5 Flow #4 Be Window a4,f4 (A) a5

X6 Flow #5 a6,f5 (A) a6

X7 Flow #6 Filter a8,f6 (A) a7

X10 Flow #7 a11,f7 (A) b0

X11 Flow #8 a13,f8 (A) b1

X12 Posit V5 Open a15,j2 (A) b2 MDC1 Mirror Downstream

X13 Posit V5 Closed a17,j3 (A) b3

X20 Posit V1 Open a21,h1 (A) c0 Vat1 Differential Pump

X21 Posit V2 Open a23,h3 (A) c1 Vat2 Mirror Upstream

X22 Posit V3 Open a25,h6 (A) c2 MDC2 Filter

X23 Posit V4 Open a27,h8 (A) c3 Vat3 Transport

X24 Posit V1 Closed a22,h2 (A) c4

X25 Posit V2 Closed a24,h4 (A) c5

X26 Posit V3 Closed a26,h7 (A) c6

X27 Posit V4 Closed a28,h9 (A) c7

X30 Vac #1 L5-80 20 l/s a31,c1 (A) d0

X31 Vac #2 Shutter a33,c2 (A) d1

X32 Vac #3 Transport a35,c3 (A) d2

X33 Vac #4 Mirror a37,j1 (A) d3

X40 FILTER A0 b1,d9 (B) a0

X41 FILTER A1 b3,d10 (B) a1

X42 FILTER A2 b5,d11 (B) a2

X43 FILTER B0 b7,d12 (B) a3

X44 FILTER B1 b2,d13 (B) a4

X45 FILTER B2 b4,d14 (B) a5

X46 FILTER ERROR b6,d15 (B) a6

X47 FILTER DONE b8,d16 (B) a7

X200 Posit V6 Open REMOTE-IO [0] VAT-POS-OPEN PIN-G (red)

X201 Posit V6 Closed REMOTE-IO [1] VAT-POS-CLOSED PIN-B (white)

X202 Posit V7 Open REMOTE-IO [2] MDC-POS-OPEN PIN-4 (blue)

X203 Posit V7 Closed REMOTE-IO [3] MDC-POS-CLOSED PIN-6 (black)

X204 T trip Dia Mono REMOTE-IO [4] REDLION PIN-1 CLOSE

X205 Ion Gauge Trip #1 REMOTE-IO [5] Clear 26

X206 Diamond water flow REMOTE-IO [6] Red 29

OUTPUT POINTS

Y0 Valve 1 Close g1 (C) 0-no

Y1 Valve 2 Close g3 (C) 1-no

Y2 Valve 4 Close g8 (C) 2-no

Y3 Valve 5 Open j4 (C) 3-no

Y4 Valve 1 Open g2 (C) 4-no

Y5 Valve 2 Open g4 (C) 5-no

Y6 Valve 3 Open g7 (C) 6-no

Y7 Valve 4 Open g8 (C) 7-no

Y20 BEPS Vacuum OK e2 (E) a0

Y21 BEPS Shutter Permit e4 (E) a1

Y26 Man Ind Lamp

Y27 Online Lamp

Y30 Filter Motor Select d2 (E) b0

Y31 Filter POS 0 d3 (E) b1

Y32 Filter POS 2 d4 (E) b2

Y33 Filter POS 4 d5 (E) b3

Y34 Filter MOVE d6 (E) b4

Y35 Filter STOP d7 (E) b5

Y36 Filter RESET d8 (E) b6

Y200 Valve 6 Close REMOTE-IO [0] VAT-SOL-CLOSE PIN-2 (black)

Y201 Valve 6 Open REMOTE-IO [1] VAT-SOL-OPEN PIN-3 (white)

Y202 Valve 7 Open REMOTE-IO [2] MDC-SOL-OPEN PIN-2

OTHER CONNECTIONS

FEEPS +24 V e1 (E) cA

Valve Gnd g5 (C) c0-c7

+24 V e11

+24 V j9

+24 V c24

+24 V e9

+24 V (E) CB

Gnd a39,a40 (A) com IV

Gnd

Gnd a19,a20 (A) com II

Gnd a29,a30 (A) com III

Gnd a9,a10 (A) com I

* Gnd b9,b10 (B) com I

Gnd d1

D4-22-106 Remote IO Wiring

Gnd PLC-OUTPUT BUS CB

Gnd PLC-POWER

Gnd MDC PIN 5

Gnd MDC PIN 7

Gnd VAT PIN C (black wire)

Gnd VAT PIN H (black wire)

Gnd REDLION PIN 2

+24 V PLC-POWER

+24 V MDC PIN 1 (red wire)

+24 V VAT PIN 1 (red wire)

+24 V PLC-INPUT CA

Serial Connections

DB9-PIN #1 PIN #1 PLC

DB9-PIN #2 PIN #2 PLC

DB9-Gnd Shield PLC

|

|

2

|

Mon Feb 6 16:23:28 2006 |

Alec | 8-ID General | EPS | Valve and flowmeter and misc. EPS wiring gifs |

| Flowmeter and valve and misc. EPS wiring gifs. |

| Attachment 1: 8ida_valve.gif

|

|

| Attachment 2: 8ida_valve2.gif

|

|

| Attachment 3: flow_meter.gif

|

|

| Attachment 4: layout.gif

|

|

| Attachment 5: plcelec.gif

|

|

| Attachment 6: serial.gif

|

|